Single Cartridge Seals

QBU

The QBU groove seal is a single pusher seal designed specifically for hot water services where cooling water is not available. Pre-engineered for moderate pressure boiler feed and boiler circulation pumps with higher reliability and longer life than conventional seals.

View QB Brochure Here

RO

A simple, proven and rugged design with dependability that has made it a favorite choice of maintenance personnel to seal ANSI chemical pumps. Heavy cross sections of the rotary components resist high levels of corrosion. Utilizing a simple rugged open rotary unit design, aggressive, abrasive and viscous fluids can be sealed easier than with other ANSI seal types that incorporate shrouded spring rotaries. The RO series is available off the shelf in standard configurations for all of the popular chemical pumps offered today.

View RO Brochure Here

DHTW/UHTW

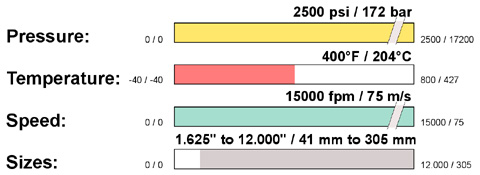

Balanced, stationary multi-spring seal, designed for power industry or other high pressure/high speed applications. Using an API Plan 23 system, this seal is used in hot applications. This seal is always carefully analyzed and tuned for balance and low face deformation for critical applications. Today’s power generation plants are increasing the need for higher parameter mechanical seals for boiler feed and boiler circulating pumps. Flowserve’s DHTW has “hot standby” capability and the ability to survive low or lost suction conditions for short time frames which are important requirements in the power industry.

UHTW As DHTW, without pumping device.

Download DHTW/UHTW Brochure Here

QB Balanced General Service Pusher Seal

Single, balanced, multi-spring, pusher seal for general service, primarily applied in the petrochemical and chemical industry. The QB complies fully with all requirements of API 682 type A. Design variations include those mentioned below and custom engineered solutions.